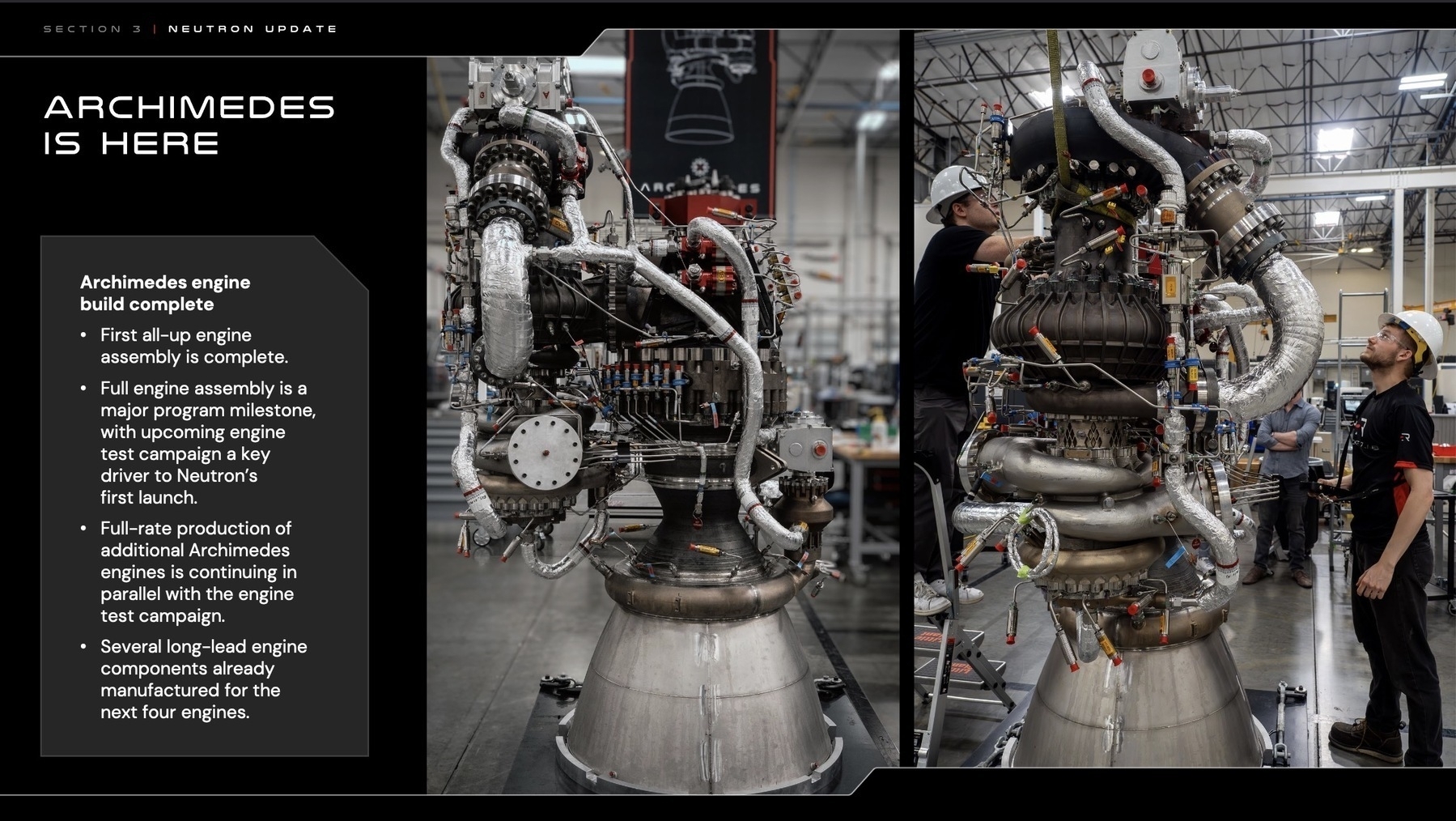

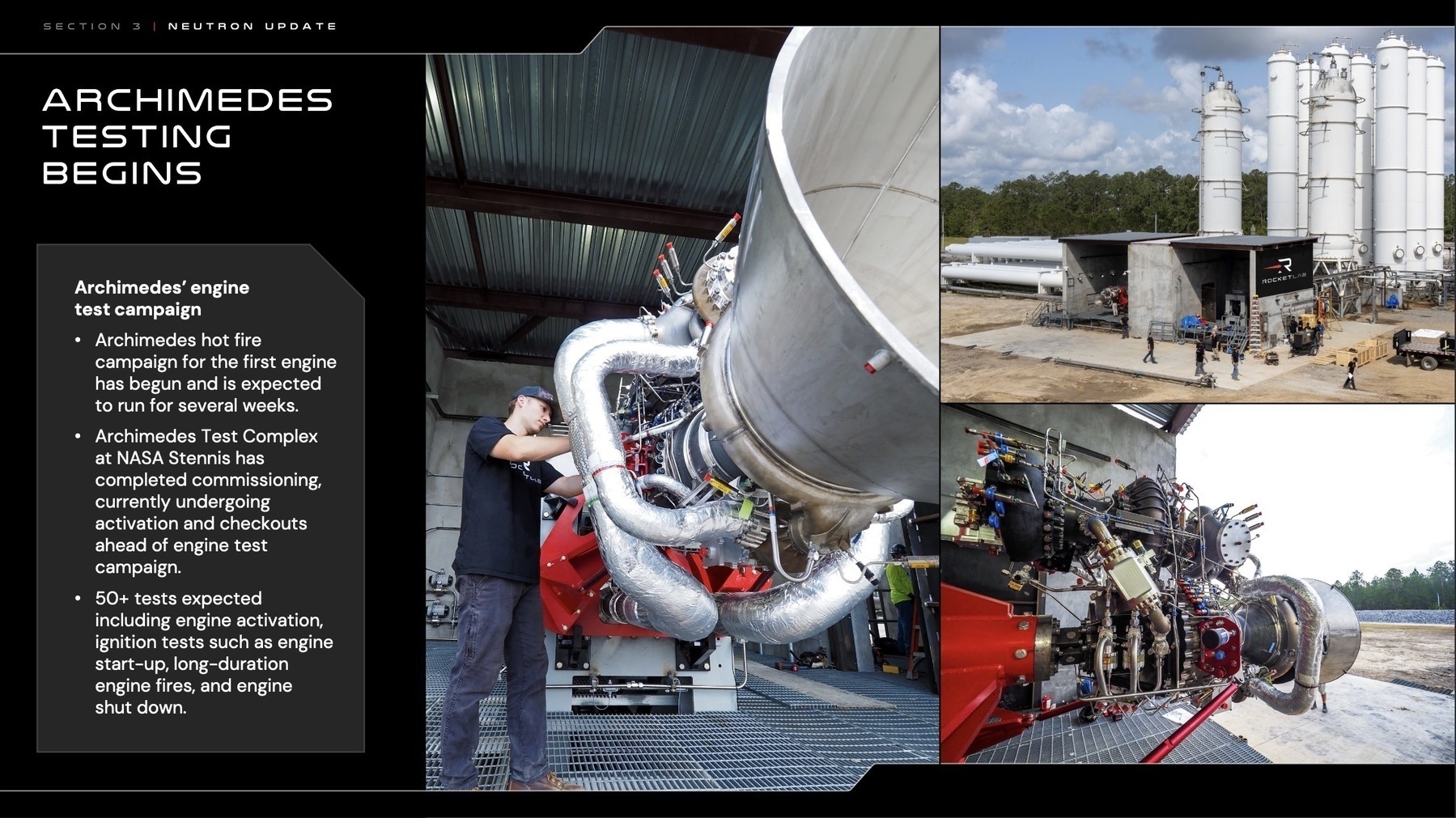

Progress Towards an Archimedes Full Stage Run

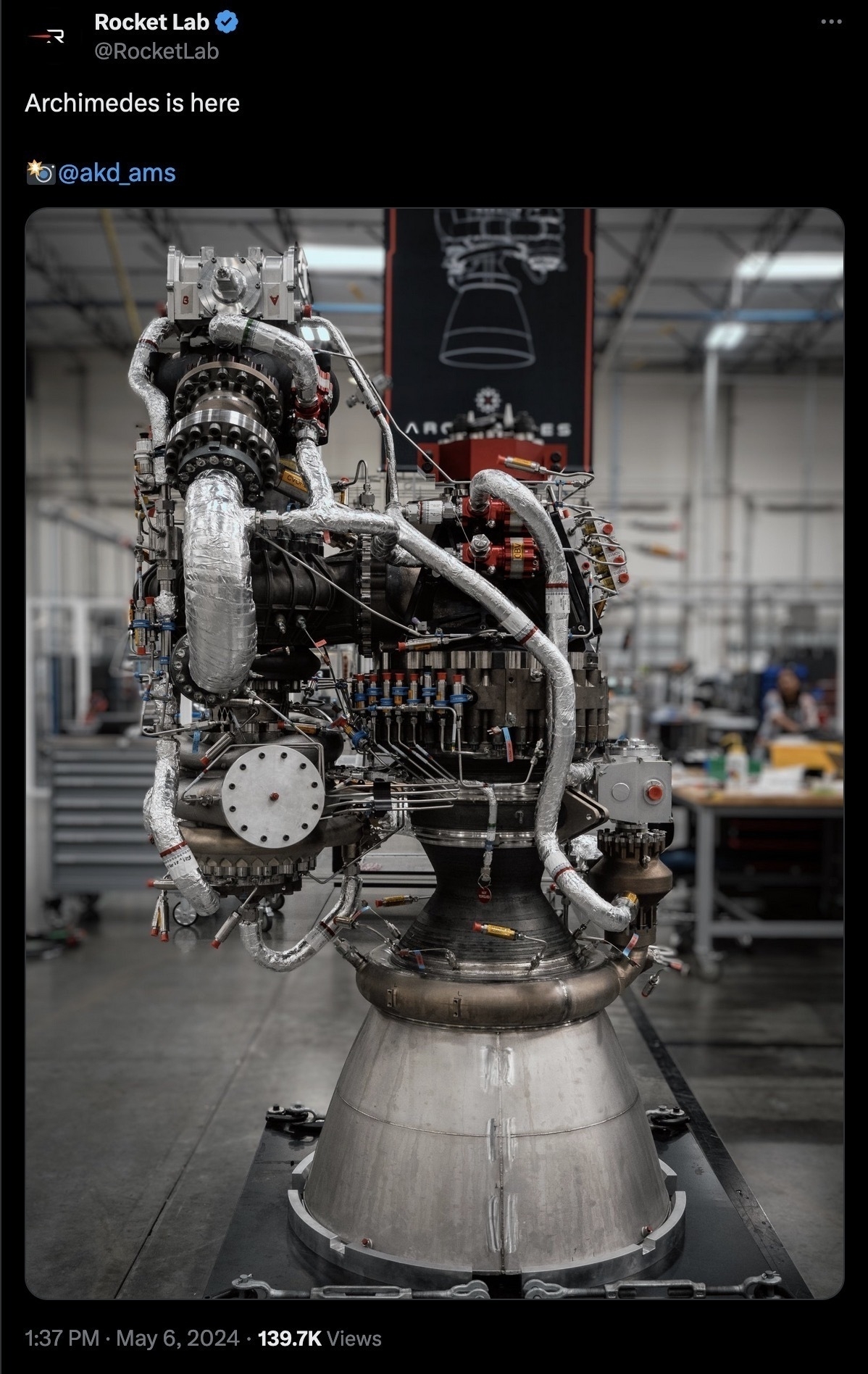

Peter Beck just shared an update on the company’s progress with Archimedes. The tweet provides a glimpse into the intricate and methodical process that precedes a full stage hot fire. This milestone underscores Rocket Lab’s commitment to precision engineering and the challenges inherent in developing reliable rocket propulsion systems.

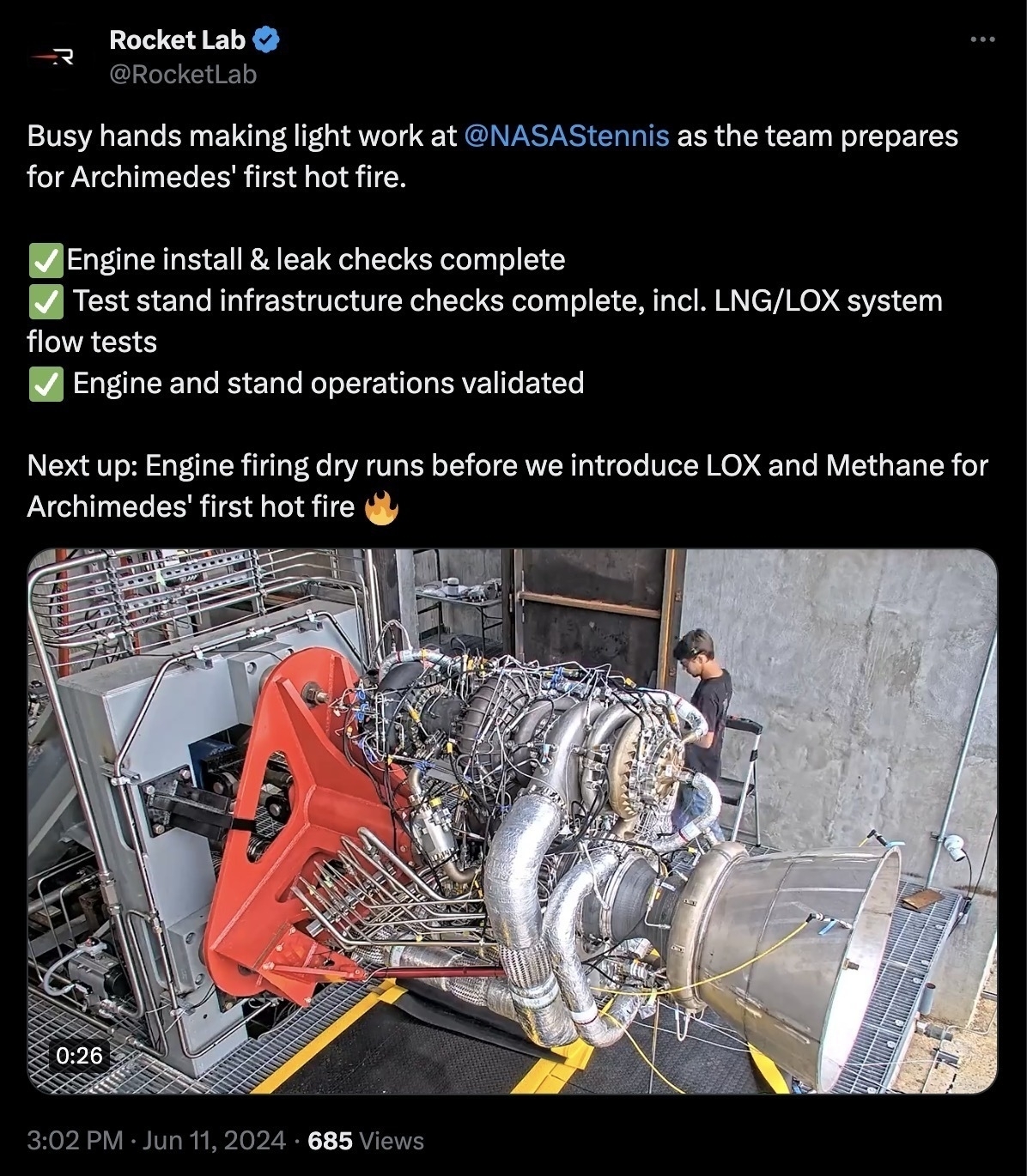

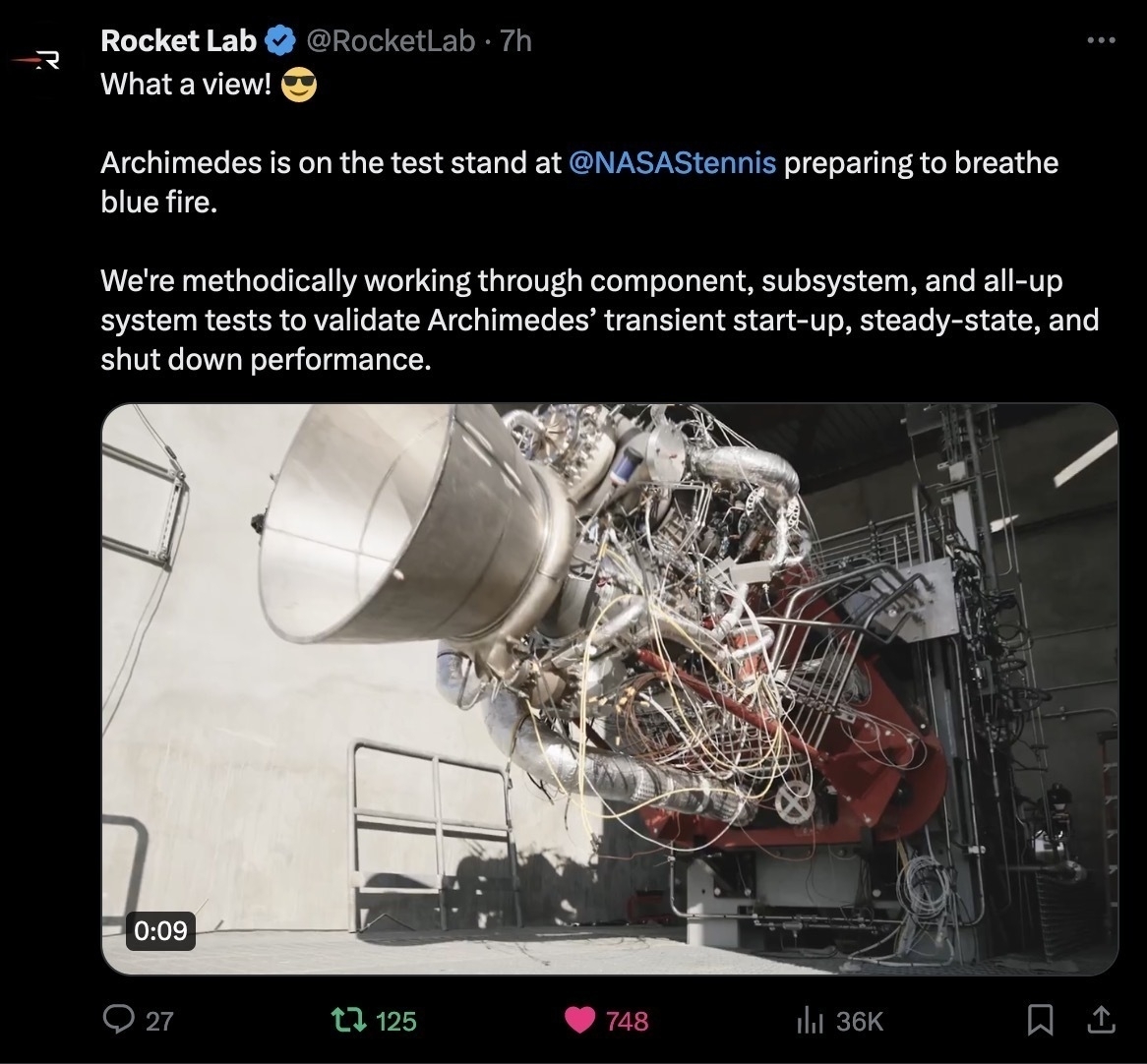

Current Phase: Pre Burner Ignition and Tuning

As Beck’s tweet reveals, Rocket Lab has successfully completed a pre burner ignition and run. This phase involves the initial ignition of the engine’s pre burner, a critical component responsible for driving the turbopumps that feed propellants into the main combustion chamber. The successful ignition indicates that the pre burner is functioning correctly, a foundational step in the overall engine testing sequence.

The next phase focuses on tuning the propellant timings. This process, expected to take a week or more, involves adjusting the precise moments when propellants are introduced and ignited within the engine. These adjustments are crucial for ensuring that the engine operates efficiently and safely. The sensitivity of these timings to start-up transients and other variables necessitates meticulous attention to detail and extensive testing.

Sensitivity to Start-Up Transients

Beck emphasizes the engine’s sensitivity to start-up transients—rapid changes in conditions that occur when the engine starts. These transients can significantly impact the performance and stability of the engine. Understanding and mitigating their effects is essential for achieving a smooth and reliable engine start-up.

Characterizing these transients involves detailed measurements and analysis of various parameters, including pressure, temperature, and flow rates. Engineers use this data to refine the engine’s design and control systems, ensuring that it can handle the dynamic conditions of start-up and operation.

The Path to a Full Stage Run

The ultimate goal of this testing phase is to conduct a full stage run, where the main valves are opened, and the engine operates at its full capacity. This stage is critical for verifying the engine’s performance under real-world conditions and ensuring that it meets all design specifications.

Achieving this milestone requires a comprehensive understanding of the engine’s behavior across a range of operating points. This includes not only start-up transients but also steady-state operation and response to various control inputs. The characterization process, therefore, involves extensive data collection and iterative testing to fine-tune the engine’s performance.

The Complexity of Rocket Engine Development

Rocket engine development is a complex and iterative process that requires a deep understanding of fluid dynamics, thermodynamics, and materials science. Each component of the engine must be carefully designed and tested to ensure that it can withstand the extreme conditions of rocket propulsion.

Rocket Lab’s approach, as evidenced by Beck’s update, highlights the importance of systematic testing and refinement. By focusing on detailed characterization and tuning, the team ensures that each phase of development builds on a solid foundation of validated performance.

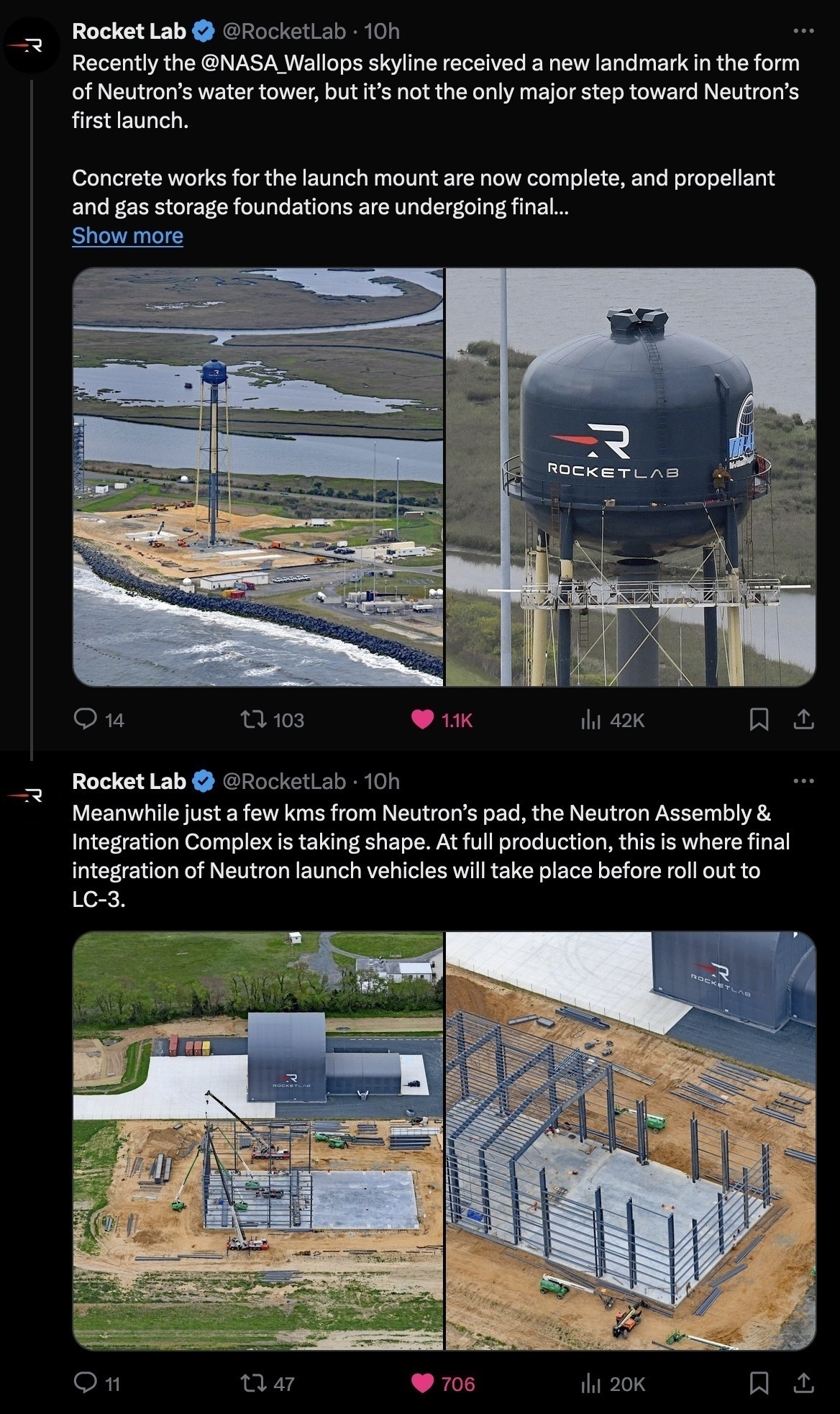

Rocket Lab’s recent progress in pre burner ignition and tuning marks a significant step towards achieving a full stage run. The detailed and methodical approach to engine development underscores the complexities involved and the importance of precision in rocket propulsion systems. As the team continues to refine their engine, they move closer to realizing their goal of reliable and efficient Neutron launch capabilities.

.

.

.

.

.

.